Perhaps the most inexpensive way to enjoy the beauty of the opal is to buy what are known as ‘triplets’.

A triplet is simply a very thin slice of natural opal, sandwiched between a clear glass or quartz cap, and a plastic or stone backing. The clear cap magnifies and protects the opal slice, and the backing enhances the color of the opal.

The whole idea is that even low quality opal can be made to look like high quality ‘black opal’, and can produce many inexpensive, but very marketable ‘stones’.

What do they look like?

This is what it looks like from the top

Click Here for a much better picture of this beauty.

How it’s done

Although you could make triplets out of low-grade opal, all you would get is low-grade triplets. Better grade and ‘gem’ grade triplets are made by starting with very fine or gem grade rough opal stone.

Note that this is a very risky business. The cutting process could reduce a very expensive specimen to worthless fragments. Imagine what this can mean if you start with a 3 ounce stone that costs $3000 per ounce !

The rough stone is held against a field of parallel diamond grit saw blades and pushed into the blades by the ‘hold down arm’:

It’s a big ugly machine that produces the intricately thin slices.

You can’t see the blades, but they are carried in a changeable block that allows one to choose the spacing between the blades.

The thickness can vary between 70 and 120 slices per inch !

To see these blades up close,

Click Here

Not for the Timid !

If you only want to make one triplet out of a fragment of a favorite stone, it doesn’t take much courage. However, if you want to go into the business of making triplets, you’d better have a strong will.

It takes between 3 and 15 hours for the saws to cut thru, and during this time, you must mind the machine to make sure that it has not bound up. Not only can you lose the opal stone, but you can destroy the very expensive saw blades !

Further, if you’re in the business to produce triplets, you need to be prepared to produce thousands every month. For this you need to have more than one of the triplet saw machines.

Not only do you have to have several of the machines, but you also have to have several different blocks of saw blades with different spacings.

Selecting and preparing the rough

Because they are going to be sliced, the rough stones must be fairly large. Smaller stones cannot be held easily against the blades. Fortunately, white-based opal occurs commonly in larger stones, but remember that this process doesn’t produce the fire. The color, pattern, and fire must already be there !

Here is a parcel of stones which have been selected to be turned into triplets.

To see a better picture of the fire

Click Here

Fabricating the triplets

After cutting, the slices must be sorted and graded, and either broken or sawed into sizes and shapes appropriate to their pattern and perhaps ‘to order’.

You must also cut just as many slices of quartz ‘caps’, and as many black stone backing pieces.

Then, the three pieces of the triplet must be glued together with a very fine jewelers cement, and left to cure. It is not necessary to polish the opal slices because the glue will fill the slight imperfections and provide the perfect refraction index.

Next, each of the rough triplets must be ground and polished. Some will become ‘freeform’ shapes, and others will be ground to ‘calibrated’ shapes and sizes.

The final product

It may seem like blasphemy to reduce a splendid opal specimen to minute slices, but, properly done, the result produces a large number of triplets which can be sold at a very nominal price. If you are skillful (and lucky), the quantity and the effort will more than make up for the differential in price.

Here is a parcel of freeform triplets.

Freeforms best preserve the pattern and color of the original stone, but they require more manual labor.

Of course the most marketable triplets are those which are cut to calibrated sizes. Unlike the freeform shapes, the final cutting and polishing of rounds and ovals can be aided by cams and jigs.

These are perhaps the most common opal triplets.

Beyond Shapes

It is also possible to create larger triplets, but this is extremely difficult to do without breaking the slices up and producing ‘mosaics’. An artist can select tiny slices and produce splendid pictures, both small and large. and where labor is cheap, designs can be specified so that a large number of stones can be produced.

Stability and Care of Triplets

Because the opal slice is captured in an air-tight sandwich, using a very fine jewelers epoxy, they are generally not subject to clouding or cracking. However, they should not be subjected to extended periods of immersion in water, nor should they be exposed to strong solvents.

Since the ‘cap’ is made of a hard stone like quartz, should it become scratched, it can easily be re-polished by a jeweler or stone cutter.

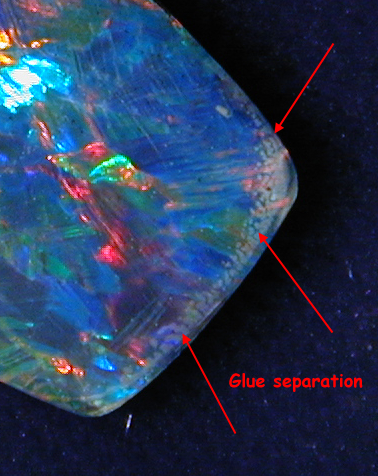

Even when the triplet is carefully made, it can happen that the glue either isn’t complete to the edge of the stone, or a separation is caused by some chemical or heat stress.

Here is a picture illustrating what this looks like:

Grading of Triplets

Of all precious gems, the opal has historically resisted all attempts to create a ‘standard’ appraisal method. There are just too many variables!

Brightness, color and pattern are still the most important qualities, and because the process does not create the fire or brilliance, full-ness of fire and directionality are critical elements.

Dealers typically appraise triplets according to their own experience, and in general, provide a scale of different ‘grades’, ranging from lower quality, all the way to ‘super gem’.

The most wonderful thing about triplets is that they provide the rich deep colors of the most treasured “Black” opal, at a fraction of the price.