Turning Chalk

into Precious Stones

Strictly from the sense of its physical formation, all opal is formed in cavities of opportunity. Sometimes the cavities are large as in ‘slides’ or ‘levels’ which produce thick solid slabs; sometimes isolated as in a clam shell; and sometimes intruding into fine fissures in hard native stone such as ironstone.

But when opal filters into ancient layers of limestone, something truly miraculous occurs.

Limestone is formed over millions of years by the death of countless microscopic plants and animals in waters and bays. The Cliffs of Dover are a well known example. The skeletons or fossils of these early life forms persist, and create myriads opportunities for the intrusion of opal, if the conditions are right.

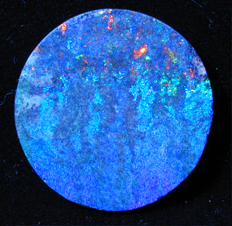

The microscopic cavities in limestone prevent the opal from forming what we recognize as solid opal with thick layers of fire. However, the opal does form the microscopic equivalent, within these tiny cavities. With the aid of a microscope, one can see a reticulated effect, varying somewhat between the eye of a dragonfly and the skin of a snake.

Limestone appears to us usually as a very white chalk-like stone. This is detrimental to the fire of any opal which has intruded the matrix. There is too much diffraction of the light for any specific color to assert itself to our eyes. Therefore, in the natural state, limestone containing opal appears to have color, but it is washed out and faint. For this reason, it was not viewed as marketable when first discovered.

But when the matrix is wetted, that unmistakable opal fire is there, and no doubt much time went into thinking about just how this material might be treated.

One place in the world where limestone matrix opal occurs, is in a small area of South Australia called Andamooka. For this reason, this material is called Andamooka matrix opal. When it is treated, it is known as Andamooka treated matrix opal. And many of the world’s experts will attest that although the Lightning Ridge black may be the most satisfyingly perfect, the treated matrix is the most brilliant.

|

They simply make your heart leap ! |  |

Who did it ?

It is not known when man first discovered that stones could be treated by fire or chemicals to enhance their qualities, but there are many precious gems today which would never see a market were it not for some sort of treatment.

We also don’t know exactly when it was that someone discovered that limestone matrix opal could be treated so as to improve the richness and brilliance of the opal in the limestone. But it wasn’t considered valuable at first, and little was seen on the market until about 30 years ago.

There’s a story about some of the first blokes who learned how to treat the matrix, and finding the temptation too great, they took some stones to another country, and sold them as genuine Lightning Ridge black opal. After the fraud was discovered, there ensued a time when nobody would buy treated matrix.

But the fabulous colors and rich black matrix of the finest stones really does offer the qualities that make the Lightning Ridge black opal so popular.

How does it do that ?

Treatment of the limestone matrix involves a fairly simple process of simmering the stones in a very rich solution of sugar in water, followed by a period of simmering in a bath of very concentrated sulfuric acid.

The action is that the sugar penetrates into the limestone matrix and then the acid ‘cooks’ it turning the white sugar behind and around the ‘pockets’ of opal, into a black carbon.

The result is that the blackened matrix surrounding the pockets of opal, does not diffract light, and the colors of the opal beam through. The quality of the finished stone is gauged by the brilliance of the fire and the richness and range of the colors.

Treating the Matrix:

sulfuric acid is extremely dangerous.

First you gotta start with the sulfuric acid. A source can be found easily in the phone book under the ‘chemicals’ section. It must be at least 95%. You cannot use battery acid.

If you are only planning to do a small number of stones, you can buy a quart or gallon, but it is much cheaper by the 25 Gallon drum (about $35).

The smaller containers are much easier to control, and the large drum requires some method of getting small amounts out without spilling.

Next, you need some glassware. There are some plastics that will resist the acid, but it’s much better just to use good Pyrex glass. I found some very nice ‘beakers’ and ‘flasks’ at a local surplus store, but even in the catalogs they aren’t very expensive.

You can use good quality glass containers for storage, as long as they have glass or rubber tops. But don’t use anything but Pyrex (heat-resistant) glass for the cooking container.

You’ll also need some glass ‘stirring rods’. Smooth, solid, and not too long for the height of the beakers.

Last, you need a good controllable ‘hot plate’.

Others talk about using ‘crock pots’ which have a temperature control, but I prefer to have much finer control, and the ability to see into the glass beaker and check the stones while they are cooking. Yes, you can ‘overcook’ them !

I use a commercial hot plate, combined with a very good thermometer. It has a ‘mid-range’ of about 170 degrees F, where it is the most accurate.

Here’s some pictures of the equipment and a batch that has just finished cooking:

|

Making ‘eye-candy’

First, you must cut and shape the stones but only polish them to a 8000 grit surface or so. You will finish the polish after the stones are cooked.

You must also make sure that the stones are absolutely dry. I choose to put the stones in a jar of methyl alcohol for at least one day before I cook. Longer is ok. Just make sure that when you take the stones out of the alcohol, don’t touch them with your fingers ! The oil in your fingers will diminish the cooking process and even make smudgy differences in the final black background.

Next, mix up the sugar and water. The sugar should be ‘refined’ pure sugar, not brown, not ‘raw’. I fill the beaker about half way, and then stir in the sugar. I find that about 8 ounces of water will absorb about the same amount of sugar.

The water should be distilled, not tap water. It is important because some water systems contain chemicals that will later react with the sulfuric acid, and diminish its effect.

I prefer to heat the water to the working temperature and then add the sugar. I can better watch the thickness of the solution as it develops into a clear syrup.

You don’t want something as thick as Karo syrup, but just a little thinner. As the sugar cooks, it will lose water to evaporation (if no top), and after 24 hours of cooking, it’s likely that you’ll have to dig the stones out of the mess.

When the sugar is dissolved, and the temperature is at 170 degF, it’s time to put the stones in.

Again, don’t touch them. I take them out of the alcohol and let them ‘air dry’ for only a few minutes, (or use a very clean cloth). Then, one at a time, I slide them in, down the side of the beaker.

The amount of time that is required for the sugar step will vary according to the softness of the limestone matrix of the particular stones. But it does not hurt at this time to cook them much longer than might be required.

I’ve seen times when only 15 minutes in the sugar is enough, but sometimes it takes as much as 48 hours. (Some folks say that they’ve had to do this for months !)

The only caveat is that you must make sure that the sugar doesn’t turn to molassas and then to hard rock candy… You can add water to the sugar if you get to it early enough. Too late, and you can’t even stir it.

And stir it you must ! Even if you have a few stones in the sugar, you must stir them frequently to allow the sugar to get to every pore in the surfaces.

Most of the time you can see that the stones have turned a golden color, but don’t expect it. Not even all stones from the original ‘mother’ will turn the same color. It depends on how uniform the original matrix was.

When you decide that they are ready, you can take the beaker off of the hot plate and let it cool. You must be careful at this point that the sugar doesn’t solidify. If I suspect that it’s too thick and may do this, I first pour off most of the syrup to the point where it just covers the stones. Later I can spoon out the stones…

When they are completely cooled, I simply wipe them off with a clean cloth and put them into a covered box until I am ready for the ‘acid’. Again, it’s tempting to handle the stones with your fingers. Admire them, but always use plastic tongs.

The ‘acid test’

Even if you have handled strong acid before, it’s very likely that you will get burned at some point in the process. Hopefully, you will only get a little drop and it will give you good evidence that you must be more careful…

Carefully fill a very clean and DRY beaker about half full with the acid.

Put the hot plate in a place where it is not in some normal ‘path’, and cannot be accidently bumped. I have lots of these places, but I choose always to put a rubber mat of some sort under the hot plate just in case.

Turn on the hot plate, and put the beaker of acid on. (not onto a hot plate)

Let the acid warm up to over 120 degF, and then, with plastic tongs, carefully drop the stones into the beaker. I have a little glass ‘spoon’, that I can use to place them on the bottom, but I never had a problem with a stone cracking by just dropping it in carefully.

After the stones are in, you will see that the acid starts to turn a light brown from the reaction to the sugar on the surface of the stones. If you have not wiped them off well, this may cause complete darkening of the acid right away. This isn’t a big thing, but it will diminish your ability to see the stones in the beaker.

Carefully raise the temperature until it is at (my preference) 170 degF. If you have a hot plate like mine, you must be careful because it will very quickly get to over 200 degF, and it is possible that the stones can crack from the expansion of the water in the matrix.

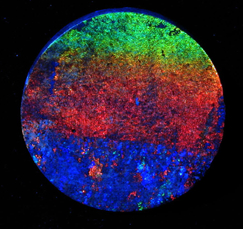

For the first hour of this process, you MUST stir the stones frequently but gently, and watch how quickly they take on their black color. You won’t want to do anything else at this point… it’s a fantastic experience !

How long !

With some matrix material, you may find that 5 minutes is ok, but 6 minutes is too much ! I’ve only found a few parcels that are this quick, but most require an hour to 24 hours.

The rate at which they change will be constant, so you can get an idea of how long it will take by watching very closely for the first hour. But in any case, you must frequently check them so that you can take them out before they become ‘over done’.

And ‘over done’ they can certainly get ! Muddy, dark, and all but worthless. The only thing you can do at that point is to sand them down and cook them again. Yuk !

As an aside, I use my home automation system to control the hot plate and to warn me of when it is time to stir the batch. In case I go to sleep, it automatically turns off the hot plate and I may have to start the cook again. But generally, I’m all a-twitter when I’m doing ‘Barbeque’…

Fully Cooked

Here’s where it takes a bit of experience to understand just when the stones have achieved the darkest tone that they ever will. Some stones will get black in minutes, others will never do more than get a little darker. Usually however dark they get, the opal in the matrix will be brighter, and that’s the whole point.

|

Some stones achieve a deep rich black, while others might turn different shades of brown. I’ve seen one parcel that turned a beautiful and sophisticated ‘grey’. |  |

What I have learned to do is to ‘cook’ some sample pieces of a parcel before I cook any finished stones. I keep records, and remember next time I cook something from the same parcel.

Often I cook stones from different parcels at the same time, and must remember that some of them must be taken out earlier than others.

But in some cases, the opal concentration is too high, and the matrix will not accept either the sugar or the acid. The stones get a dark ‘honey’ color perhaps, but will never ‘cook’ beyond that point.

Taking them out of the acid

Whenever you take them out, you must do so very gently, and using the glass rod or tongs. If all are to be taken out at once, then I choose to pour off the acid into another beaker first.

Then I let them cool for 15 minutes or so before I dump them into another bath of cool but more diluted sugar-water. Leave them in this solution for an hour or so, and then take them out, and wipe them off with a clean cloth. Discard the cloth, it will soon disintegrate from the acid.

A little polish and they’re finished

The stones still need to be given a final polish. But here you can really screw up the stones. If you find that you did not surface them well before, you will be tempted to do so now.

But if you grind too much, you will begin to see a lighten-ing of the background color. When this happens, it most often means another trip thru the process.

If you did a good job before the cook, then the surface will only need a quick polish, and it’s finished.

You will find that it is almost always impossible to put the same kind of polish on a matrix opal that you can put on solid opal. I’ve seen some that are almost perfect, but most of the time you will not be able to get rid of the ‘granular’ surface effects.

Well….Almost

Within a few hours and over a period of days, you may see the stones ‘weep’.

This is normal, but some parcels weep more than others. You must keep the stones where you can watch them and periodically wipe them off. The liquid that is weeping contains a lot of acid, and will eat just about any material. After a while, this will stop. If it does not, you may put them back into a light sugar solution and let the acid weep out into that. When you can no longer see any dark wisps of color coming from the surfaces, take them out..

This weeping may slow greatly, but may still continue for several weeks or months. I prefer to keep the stones until I am sure that it has stopped. I have tried other methods of stopping the reaction, but all have resulted in some kind of ‘haze’ or ‘dust’ on the surface, which, being microscopic, is impossible to remove completely, and is always disappointing.

A little more detail:

Although most of the matrix found at Andamooka is broken into small boulders and pebbles, it is sometimes found in large slabs. When these slabs are broken, it is found that the opal is indeed rare and spotty. Therefore, not all limestone from Andamooka yields precious matrix opal.

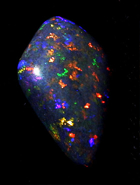

When opal occurs in matrix, it is found in different grades; varying with the concentration of opal, the granularity of the matrix, and natural inclusions.

Concrete ?

Where the granularity of the matrix is coarse, the stone will not take a polish, and even with a large concentration of opal, it is forever dull unless it is wetted or kept in water. This type is called ‘concrete’, and mimics a type of matrix opal found in Honduras.

When the granularity of the matrix is very fine, there is very little limestone to affect, and the opal cannot be enhanced. This does not mean however that stones of this type cannot be very beautiful of their own without treatment, and even with it.

When the concentration of opal in the matrix is low, of course, there is little reason to mine it. However, larger boulders must be still broken in order to discover small patches. This process greatly adds to the cost of mining matrix opal.

The concentration of opal in the matrix may get so high that treatment is useless and the material is technically solid opal. Stones cut from this material show rich swirling colors but do not have depth, and are slightly translucent.

Another factor affecting the treatment process, is the concentration of dolomite in the matrix. Dolomite is simply limestone which is more dissolved and therefore lacks the permeability necessary for the treatment process to succeed.

Only when the granularity of the matrix and the concentration of opal is balanced just right, will the matrix accept the treatment process.

Inclusions are another element which must be considered when cutting and treating Andamooka matrix opal. As a sedimentary rock, limestone contains various inclusions of softer and harder pebbles, fossilized plant and animal remnants, and sometimes, pockets of solid opal.

Depending on the hardness of the inclusion, it may darken differently from the surrounding matrix when treated. Some inclusions are too hard, and remain light colored or appear ‘dirty’. Softer inclusions may darken beyond that of the matrix.

Often the cutter can take advantage of these inclusions and create ‘picture stones’ which although often obscure, sometimes are startlingly depictive. More often however, these inclusions reduce the appeal and value of the cut stones.

Another problem for the cutter is that of orientation or ‘facing’ the stone. Andamooka matrix is treacherous in that the opal follows natural flows and changes in the composition of the limestone and because the stone is opaque, it is more difficult to predict the direction that the fire will take when shaped and then treated.

The most precious and rare of the Andamooka matrix opal occurs as a careful balance of a soft dolomitic limestone with a medium concentration of opal which has formed in vertically hanging sheets within the matrix. Generally these can be identified readily, even on the field, where larger flakes of fire can be seen in one orientation or another.

Regarding the value of Andamooka matrix opal:

First and foremost is the intrinsic beauty of the final gems. Andamooka matrix exhibits the exact same deep rich colors against a deep black background as does its far more expensive Lightning Ridge cousin.

Next, and probably most importantly, the rarity of the material. Andamooka is a small township north and west of Adalaide along the Stuart highway in South Australia. The precious stones field established around the town is only 5 Kilometers by 13 Kilometers, and being a very small town, (about 300 people), the hardships of life there are very trying.

There are very few opal miners at Andamooka, and even few look specifically for matrix opal. Andamooka primarily is known for a very fine solid crystal opal which exceeds the beauty of that of the Coober Pedy fields to the northwest. This material sells for ten times more than does matrix.

When one considers the amount of opal in the limestone, it is frequently greater by mass in ratio to the matrix, than in boulder opal or other matrix opals.

The fact that it must be treated seems to be the one factor that is limiting the current market perception of Andamooka matrix opal.

The treatment of gems has been practiced since prehistoric times, usually to make them appear to be some more valuable stone. Indeed, when Andamooka matrix is treated, the result emulates the best Lightning Ridge solid black opal. The difference however is that we are simply providing a background for the opal that is already in the stone. The process does not alter the opal, or add opal, or any other brightening or clarifying agent.

It is the opinion of many opal dealers that Andamooka matrix should enjoy a market price which is equivalent to that of other matrix or boulder opal, in that it should be somewhere between 10 and 20 percent of that of solid black opal.

Regarding the health and stability of Andamooka matrix opal:

The treatment penetrates only about one to two millimeters (maybe less) into the material. Therefore, if the stone is gouged deeply, the white base material will be visible. Within reason, the stone can be re-cut, polished, and treated with good success. Should the stone ever be cracked, it can be repaired with greater success than solid opal due to the fact that it is opaque.

The treatment is permanent and care is identical to that of solid opal with one exception. Solid opal will not be affected by detergents or bleach, but exposure to these chemicals without rinsing may cause a light ‘haze’ to develop on the surface of these stones. If this occurs, it can be corrected by re-polishing, or more simply, by a touch of a light body oil.

As with solid opal, various qualities of this material exist. And similarly, the highest qualities are the rarest, possessing brilliance and richness of colors which are the equal to all but the finest ‘solid’ black opals.

Last words

Buy finished stones or plan to cut and treat the rough yourself. Don’t buy rough and then have someone else treat it. This may be the only choice you have, but you will be missing out on one of the most interesting, surprising, and satisfying experiences in your life !